Riding a bicycle in good condition is not only a pleasure for those who ride it, but also contributes to your own safety. After all, imagine that during your ride with your vintage steel racing bike your tube flies off, your chain slams or your wheel is constantly dragging against your brake pads to name just a few inconveniences.

Not really pleasant and perhaps a reason to keep your vintage steel bike in the stable or closet.

That's why it's important to inspect the condition of your bike before you go.

If you drive a lot of kilometers in a year, it is recommended to bring your bicycle to a bicycle repair shop at least once a year. Usually this does not apply to the vintage “oldtimer” racing bike and is only used occasionally for a retro race, a short ride or a ride with the retro club.

You can therefore perform many checks yourself and in this article we will help you with this.

Checking the brakes

Calipers and brake pads

To make sure the brakes are working properly, you must first inspect the condition of the brake pads (the rubber pad that makes contact with the rim). The pads must have grooves to drain water: if these are not visible, it means they are too worn out and need to be replaced.

Also check for cracks in the rubber. After all, dry or damaged brake pads reduce braking efficiency.

Brake levers

The brake levers should feel smooth and return to the starting position quickly. Failure to do so is usually an indication that the cables are corroded and should be lubricated. Periodically check the strength of the return spring (on the back of both calipers).

The brakes must work powerful and efficient, the brake pads must not drag against the rim as long as the brake lever is not engaged. If this is the case, the brake calipers are not centrally positioned.

Handlebar and headset

The handlebars and fork should turn smoothly and not stop or scratch at any time. You can check the proper functioning of the headset in the following way

Place your hands on the handlebars and keep the front brake pressed. If you feel a movement in the ball head, it is loose. Also bounce the front wheel off the ground, if you hear a rattling sound, this can also indicate a loose headset.

Tires and tubes

The tread of the tire or tube must be visible and must not have any cracks that could indicate dry rubber, which reduces traction on the road. Dry tires or tubes also increase the risk of punctures due to reduced elasticity.

Tubes must also be well glued to the wheel, as you don't want a tube turning off while driving.

The bottom bracket

The bottom bracket is the motor of the bicycle and therefore very important. To check these, it is best to place the bicycle on a bicycle repair stand (bicycle holder) and remove the chain from the crankset so that the crank arms can turn freely. The rotation of the crank should be smooth and without friction.

If there is movement, it is best to go to a bicycle repair shop to tighten the bottom bracket unless of course you have the equipment to fix it.

If the problem is not solved after that, this indicates a problem with the ball bearings.

Wheels and hubs

Checking the wheels for alignment can be done without removing them from the bicycle. Test one wheel at a time, spin the wheel and use the brake pads as a reference to see if the wheel is centered.

If the wheel is centered but it's not straight, you can take it out by tightening the spokes. If you have never done this before, this can be a time consuming activity.

The best way to check the wheel hubs is to move the wheel sideways with the bike on the ground. If there is movement, the hubs must be tightened.

Tire pressure

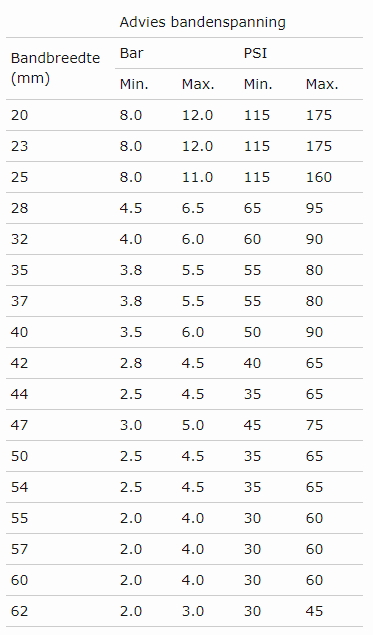

The tire pressure is often neglected, but it makes cycling so much more pleasant with the correct tire pressure. It is measured in bar or psi and is proportional to the weight of the rider. The following table shows the minimum and maximum pressure for racing bikes on paved roads.

Tire pressure should be about 0.5 bar or 7 psi lower on wet roads. On unpaved roads, the pressure can be reduced by 1.0 bar or 15 psi to increase grip and comfort. Tubes should generally be inflated to a pressure of 0.5 bar or 7 psi.

Modern tires and tubes usually have instructions on the packaging and on the tires or tubes for the recommended maximum tire pressure.